Merus® Control and Protection System (C&P)

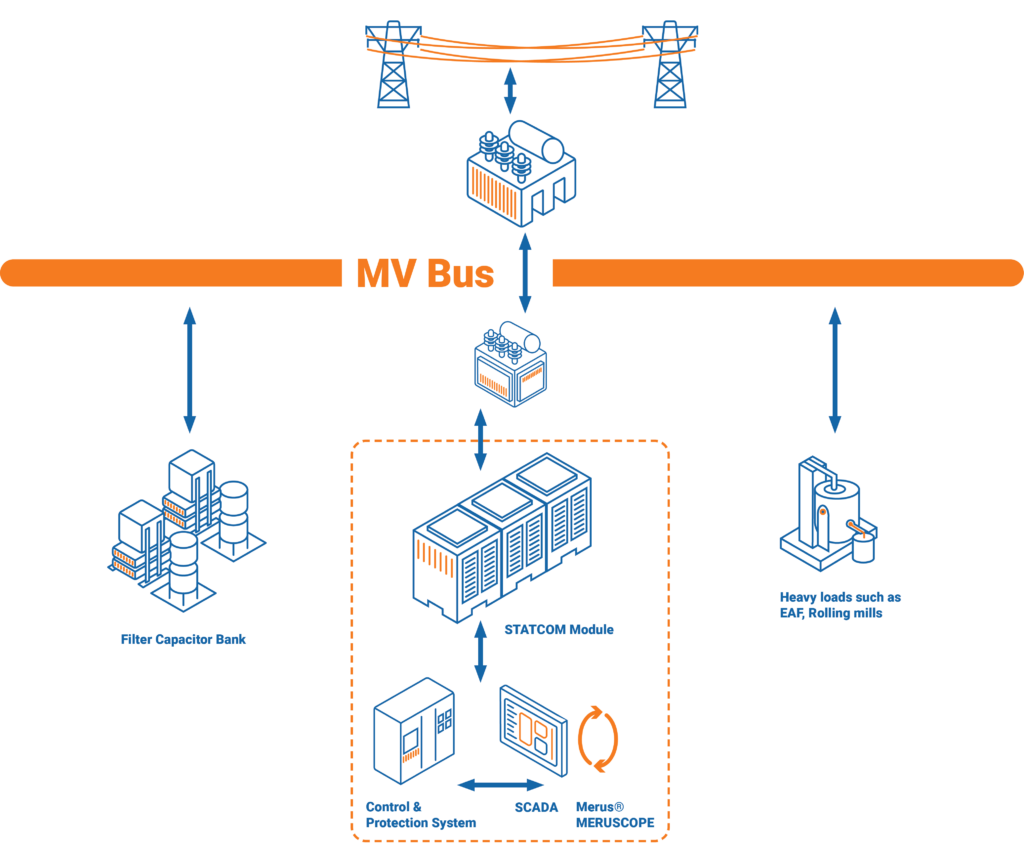

- The C&P system serves as an integrated control cubicle essential for managing and safeguarding the entire Merus® STATCOM system. It includes necessary software and hardware for operating Merus® STATCOM modules and controlling additional components like Filter Capacitor Banks and field equipment, while also handling system-level protection functions.

At its core, the C&P system employs proprietary software crafted by Merus Power’s experts in Finland, pivotal for ensuring the system’s performance and reliability. This advanced control software runs on a modern platform and is responsible for all system-level controls, relaying commands to the STATCOM modules through a fiber optic link.

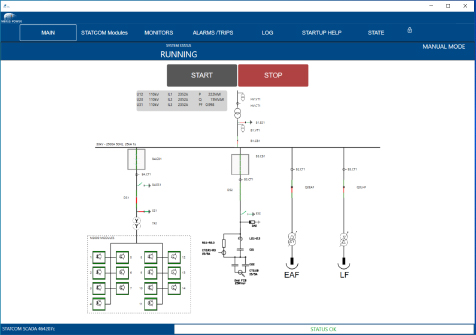

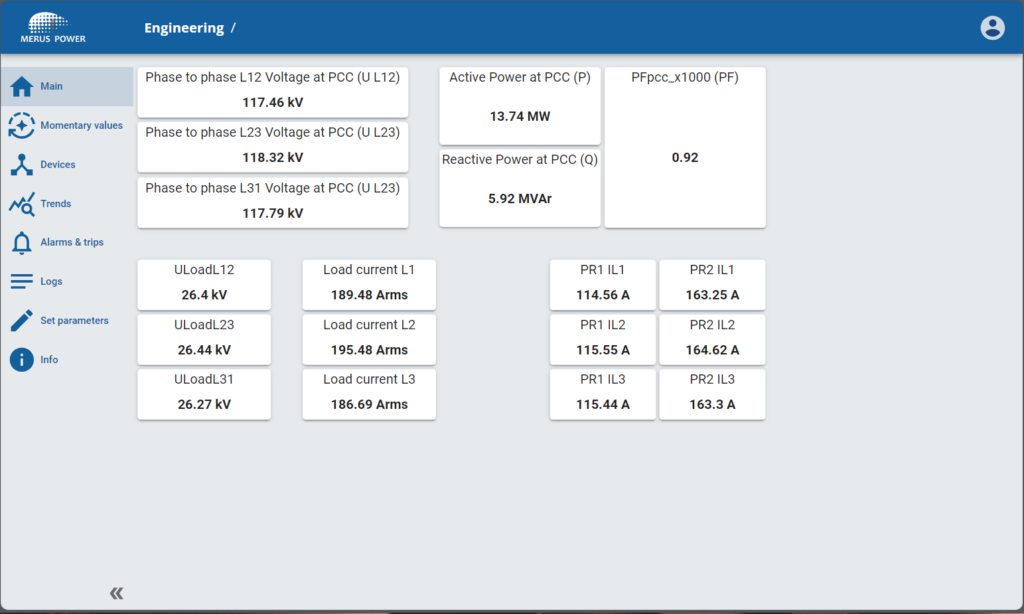

- The system incorporates the Merus® SCADA system (Supervisory Control and Data Acquisition), which operates on an industrial-grade PC equipped with a 19” touchscreen interface, enabling streamlined communication and data acquisition. This platform allows for easy operation management, including start and stop sequences, and logs every event for convenient data retrieval and external transfer.

- Furthermore, Merus® MERUSCOPE™, an optional cloud-based IoT service, can be integrated to enhance the C&P system. MERUSCOPE™ facilitates comprehensive remote monitoring and control across the Merus® product range, delivering real-time surveillance and alerts to address issues promptly. This service minimizes downtime and reduces maintenance costs, while providing access to historical data for trend analysis and strategic planning in power quality.

Merus® STATCOM modules

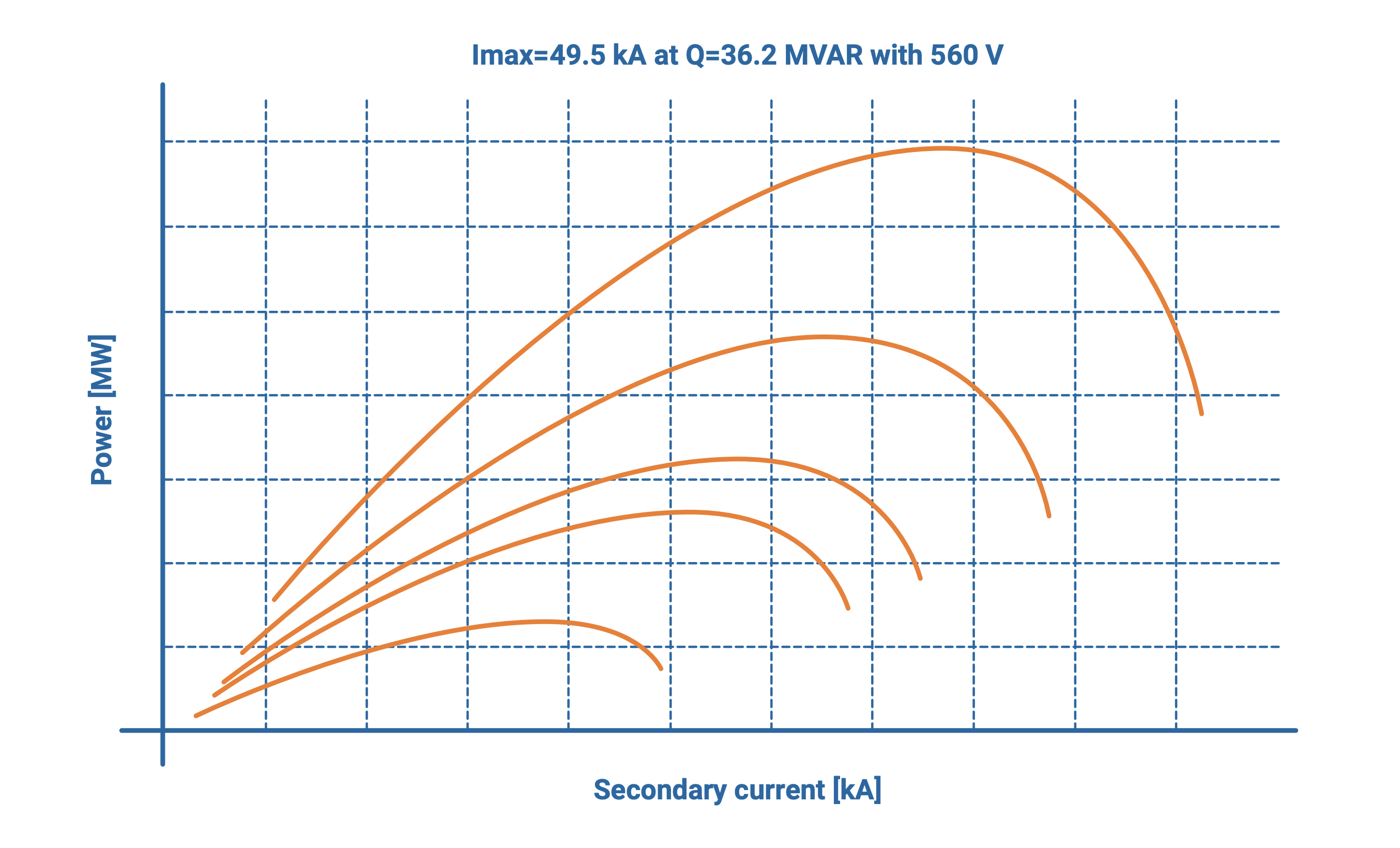

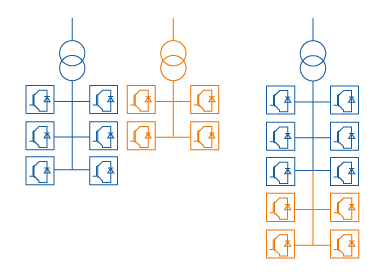

- Merus® STATCOM modules are the main building blocks of the STATCOM system, including types M2000 and PCM. These modules function independently, controlled by the C&P System, and are connected in parallel to achieve the necessary reactive power output.

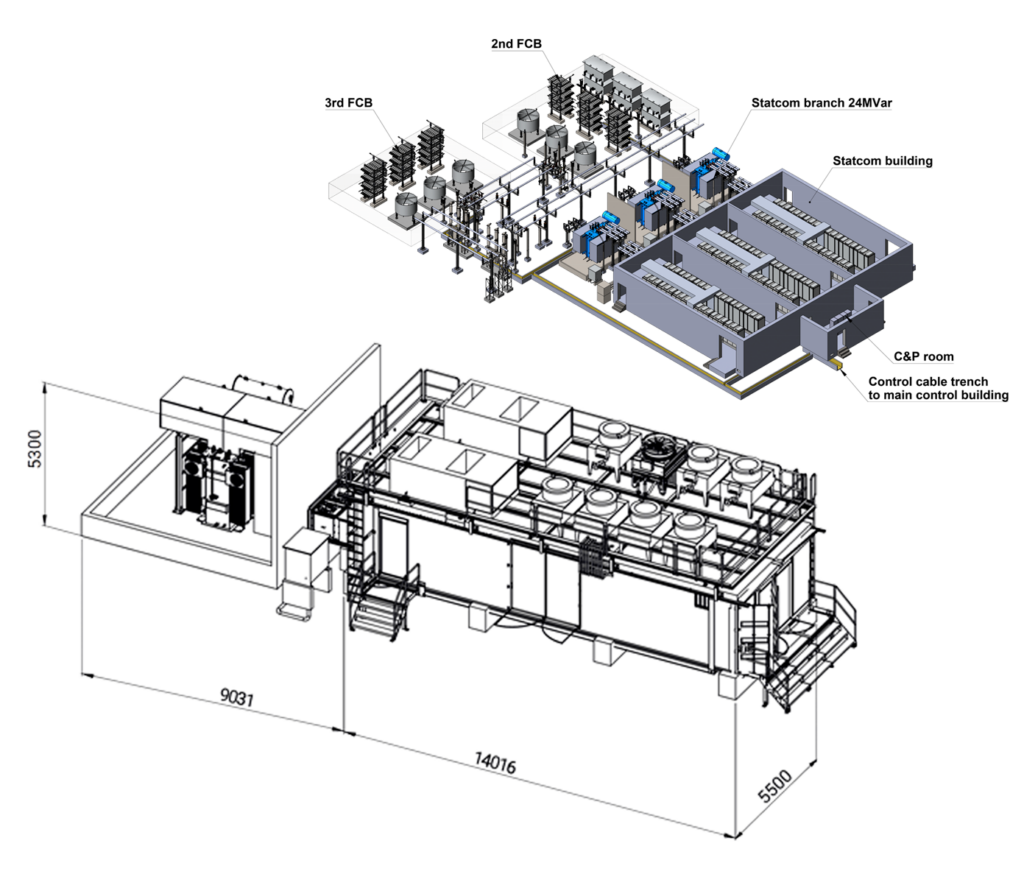

The M2000 is designed for more demanding indoor applications and requires installation in containers or buildings, while the PCM is aimed at outdoor use, specifically for power factor control, and does not require any housing. All modules are manufactured and tested at Merus Power’s factory in Finland.

- The individual modules of Merus® STATCOM are grouped into blocks according to system requirements and connected to a medium-voltage bus through coupling transformers. This setup allows for scalability, making it easy to increase power in the future by adding more modules or module groups.

- The reliability of the compensator system is critical. Each module is designed as an independent unit with its own control and protection functions. If a module fails, it disconnects without disrupting the remaining modules, which continue operating seamlessly. Additionally, each module has an independent cooling system, enhancing overall reliability.

Users can monitor module-level measurements and events, such as trips or alarms, through Merus® SCADA. Despite the modules operating independently, control is automated, allowing users to simply start or stop the entire system from the SCADA interface.

Filter Capacitor Banks (FCB)

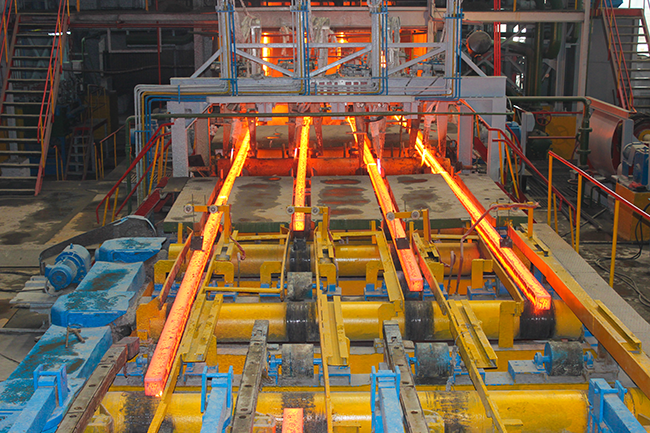

Depending on system needs, the Merus® STATCOM system may include Filter Capacitor Banks. These banks help lower the CAPEX cost in applications focused mainly on capacitive compensation and provide efficient harmonic filtering for frequencies beyond the scope of power electronics-based modules. The design of these banks is complex and tailored case-by-case by Merus Power’s in-house design team, using only audited and reliable suppliers.