Additionally, the operation of motors and pumps in these machines creates inductive loads, consuming reactive power and resulting in a low power factor. A low power factor indicates an inefficient system that requires more current to deliver the same amount of power. Power factor correction, often involving the installation of capacitors, is needed to improve system efficiency and reduce reactive power.

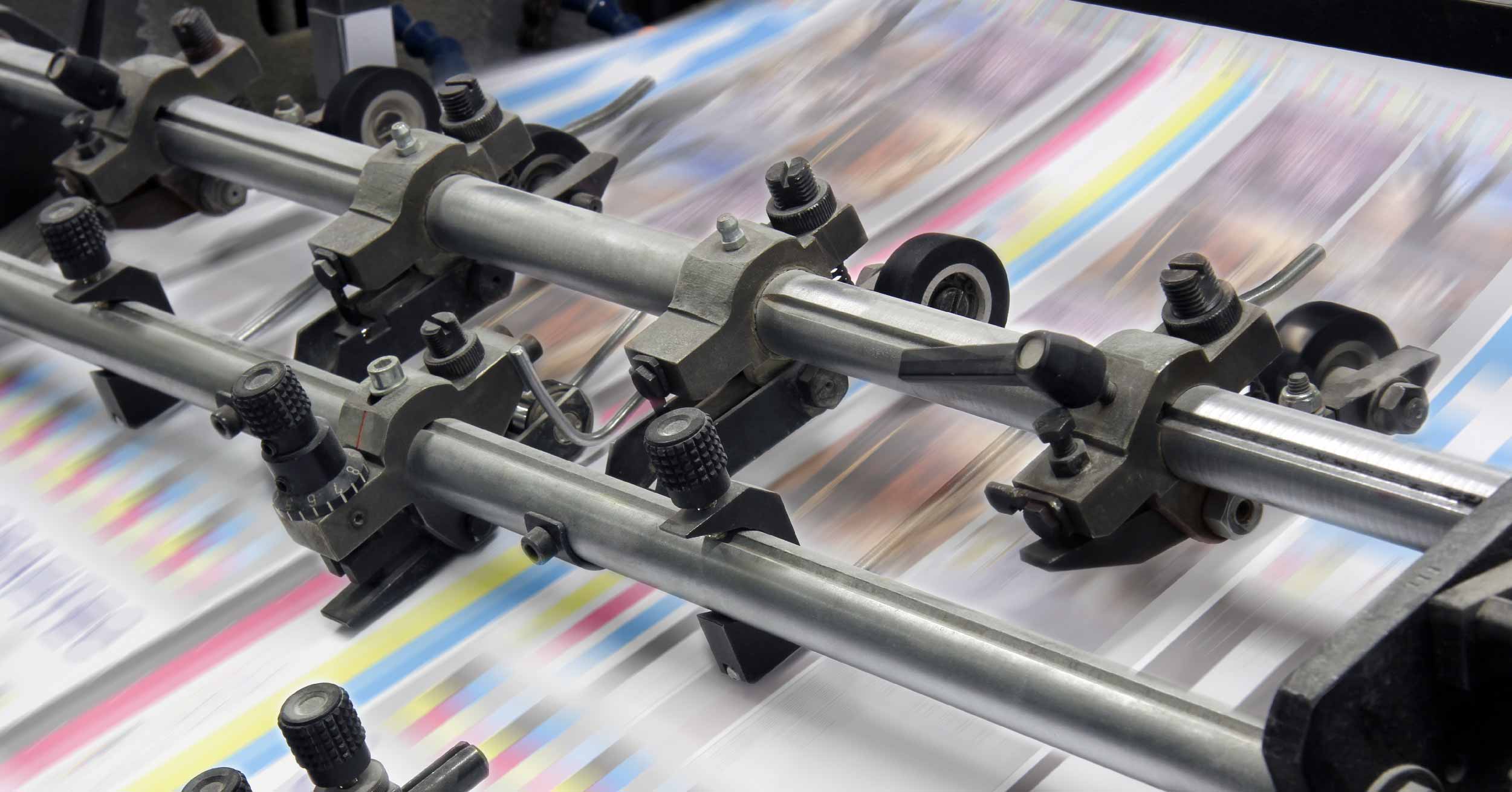

Poor power quality can result in several issues, including unexpected downtime, which is costly for any business but especially for industries like printing houses where continuous operation is often essential. Therefore, it’s crucial for printing houses to prioritize maintaining high power quality. Failure to do so can lead not only to equipment malfunctions and inefficiencies but also to significant operational setbacks, including unplanned stoppages. By addressing power quality issues like harmonic distortion, voltage fluctuations, and low power factor, printing houses can improve their system’s reliability and efficiency, thereby minimizing the risk of downtime and other operational difficulties.