Reactive power, the reason behind inefficiency and hidden costs

Most likely reactive power is causing you to pay remarkable amounts of money every month without you even realizing it. Wouldn’t you rather use energy to do productive work than heat the wires and electrical components of your installation? This is exactly the case when it comes to reactive power and power factor.

Let’s slow down a bit. First, what is reactive power?

Electrical equipment such as machines or motors consume energy. This energy is partially converted into other forms of energy like mechanical energy, thermal energy, or light. All the energy that gets converted and used effectively is what we call active, true, or real power (kW). However, the same system can absorb or produce energy that gets lost and doesn’t get converted into other types of energy. This is called reactive power (kvar) and it is necessary for the correct functioning of devices.

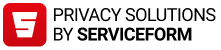

Reactive power creates an additional load on the cables, wires, and electrical equipment itself. Too much reactive power can cause overheating of the components which significantly shortens the lifetime of equipment. In addition, it can contribute to unintended shutdowns, power losses, blackouts, and even fines for not complying with power quality standards and regulations.

All in all, reactive power negatively affects electric efficiency and causes unnecessary energy losses, shorter lifetime of components, higher energy consumption, and other extra costs.

Let’s talk about power factor.

The combination of active and reactive power is referred to as apparent power. Power factor (PF) is the ratio of active power to apparent power.

In an ideal world, the desired power factor would be exactly 1.00, which would mean that only active power is transmitted. This is rarely the case though as most machines and motors need some amount of reactive power to operate.

So, what is still considered good power factor?

Generally, an uncorrected industrial system operates at an average power factor of 0.80, which means only 80% of delivered power is useful, active power. This is still considered good power quality however it is not totally ideal. Power factor 0.80 means an additional transmission of 25% power.

In other cases, the power factor could go as low as 0.50, and this way the system not only consumes 100% more power but the risk of potential overload and power failures becomes more and more possible as well. This eventually means even more and larger financial losses.

To sum it up, anything below power factor 0.80 should be taken care of to save on consumption, comply with power quality standards, and save money, energy, and nature. In many cases, the limit set by distribution system operators can be more strict.

What causes low power factor in the first place?

The main cause of low power factor is inductive loads. For instance, induction motors, transformers, generators, arc lamps, or electric furnaces. But also capacitive loads, variations, and underground cables.

Power Factor Correction, how to do it?

Power Factor Correction (PFC) is the term for any equipment installed into an electrical system that compensates for reactive power and improves electrical efficiency.

In some countries, the end users are charged for both active and reactive power, even though only active power is doing useful work in an electrical system. Higher reactive power and lower power factor mean more expensive electric bills to pay. Correcting the power factor reduces wasteful reactive power and this way significant money savings can be achieved. The amount of savings depends on the amount of reactive power prior to power factor correction actions.

Our PFC solution – Merus® A2 – Active Harmonic Filter

The trustworthy Merus® A2-Active Harmonic Filter can solve all main problems in your electrical system. One device, but many solutions to help you save energy, achieve higher productivity, decrease downtime, and extend the lifetime of devices and components.

- Power factor correction

- Voltage variation control

- Harmonic filtering

- Flicker mitigation

- Balancing power imbalance

- Load balancing in three-phase systems

Reference: Securing operations in one of the largest data centers in Asia

A large data center in Asia suffered from severe harmonic distortions caused by electrical equipment, such as LED lighting, computers, and UPS systems. After measurements, a solution of Merus® Active Harmonic Filters was suggested and installed in 3 distribution boards parallel to the loads. Harmonic distortions are now below the allowable limits thanks to the fast response time and robust design of the Merus® Active Harmonic Filters. The power factor was improved close to unity at 0.97-0.99. The building is now meeting power quality standards.

Merus® Active Harmonic Filters provide a perfect solution for real-time cancellation of harmonic distortions to ensure compliance with IEEE 519, G5/4, EN 50160, and also other power quality standards and regulations. Providing higher productivity, reduced maintenance costs, and longer equipment lifetime.

Reference: Solving power quality and power factor issues in an automobile gear factory

An automobile gear factory in China was suffering from poor power factor, harmonic currents, and overall poor power quality. The solar power system connected to the factory was just further aggravating these issues. After thorough measurements, a Merus® HPQ solution was suggested and installed into the system.

After installation, the power factor increased from 0.40 to 0.95 and the THDi reduced from 40% to <10%. The stability of the electrical system and the lifetime of the equipment increased. Overall better power quality was achieved, and the system is now also compatible with power quality standards and recommendations.

The Merus® HPQ solution consists of a detuned capacitor bank and an active harmonic filter in an all-in-one cost-effective and economical solution. It offers better performance than traditional capacitor banks with fewer problems and reduced electric bills.